Ground Level Container Delivery

Tilt bed trailers are the most commonly used shipping container delivery method. The bed of the trailer will tilt upwards to allow the container to slide off and into the desired position. This means that the driver will arrive on site and should require no additional equipment to set the container on the ground provided all of the following criteria are met:

Door Loading Direction

Ground Preparation

Site Access

Straight Line Clearance

Door

Loading

Direction

Doors to cab

The truck backs into position to tilt the container onto the ground. When the truck is loaded with the container doors facing the cab, the shipping container doors will be the last part of the container to be placed onto the ground.

Doors to rear

The truck backs into position to tilt the container onto the ground. When the truck is loaded with the container doors facing the rear, the shipping container doors will be the first part of the container to be placed onto the ground.

Incorrect loading can result in additional fees and possibly, an unsuccessful delivery.

Ground

Preparation

The ground must be firm, dry and level to ensure a successful delivery.

Delivery must be on firm ground that can support the combined weight of the trailer and container to prevent sinking.

We are often asked how to prepare a site to ensure the container is sitting on level ground. Best practices include placing the container on a concrete pad, pavement, crushed gravel bed, railroad ties, wood, etc. to ensure door functionality and maximize life span.

We also strongly recommend that the container does not sit directly in grass or on surfaces where water can pool in order to extend the longevity of your sea container. Excess moisture can rot the undercarriage of the container which can affect the structural integrity of the flooring.

Inclement weather can present challenges and impact delivery operations.

Ready To Order?

Questions about delivery conditions?

Call our team to ensure a successful delivery

Site

Access

The trucks used to deliver 20ft shipping containers are big. The trucks used to deliver 40ft shipping containers are bigger. These trucks require significant space to enter the property and maneuver into the final delivery position. Site access includes ample turning radius into the property from the roadway. Rural two lane roads are often not wide enough to accommodate the turning radius of a 40ft container delivery truck. The entrance into the property and the space for the truck to maneuver into position should also be considered. Site access can be limited by low hanging power lines, tree branches and other potential obstructions.

Driver clearance on either side: 1′

Minimum width clearance: 14’W

Straight

Line

Clearance

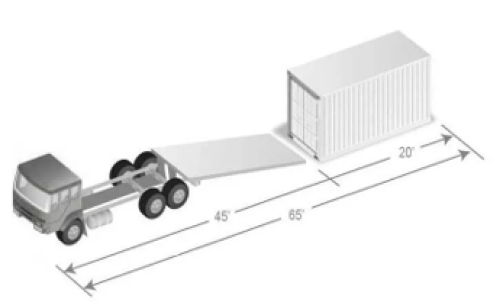

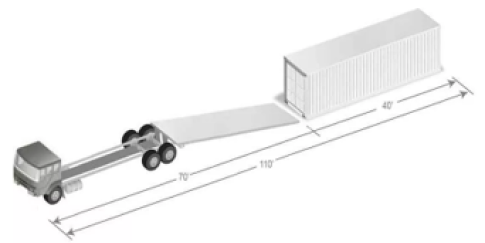

Once the delivery truck has entered the property, the trailer will require sufficient space in a straight line to deliver into the desired spot. This is known as straight line clearance. This clearance is critical for a successful delivery. This space requirement includes the length of the truck, the trailer, and the container as shown below.

20ft Container Delivery

For the delivery of a 20′ container,

the truck will require a minimum of 65 feet of straight-line clearance.

40ft Container Delivery

For the delivery of a 40′ container,

the truck will require a minimum of 110 feet of straight-line clearance.

Delivery Day

The on-site contact provided should receive a call in advance, either the day prior or upon leaving our yard,

to confirm the delivery time frame.

When all the above conditions are met, the container delivery process should take approximately 20 minutes. Any additional delays for waiting time, inadequate space, improper container loading instructions, etc., can result in extended delivery time and potentially additional costs.